6.1.16 Springs

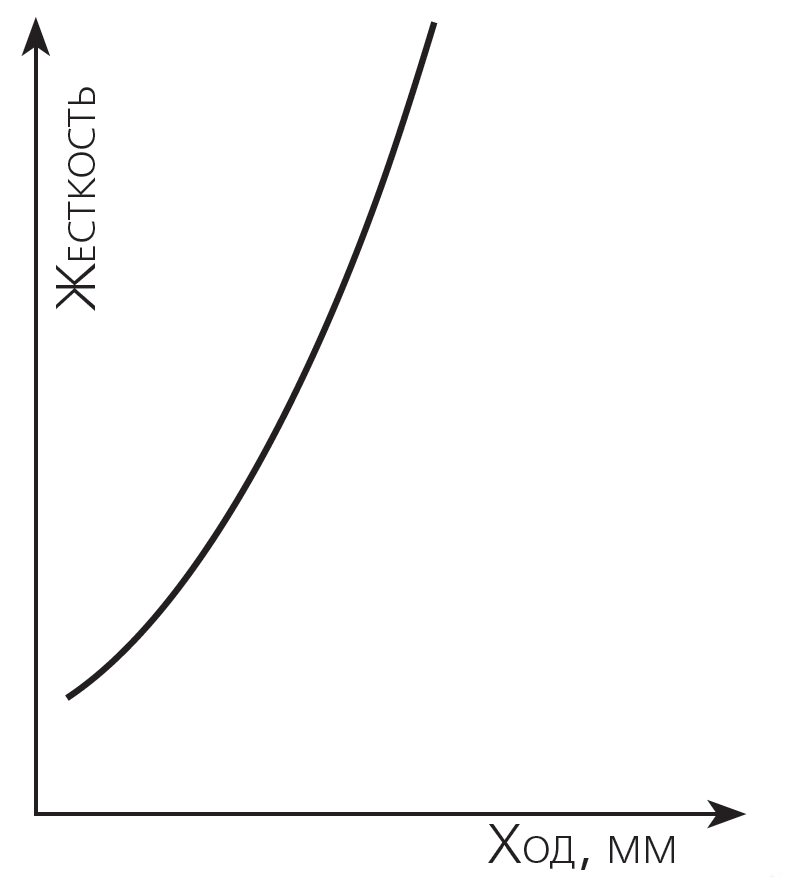

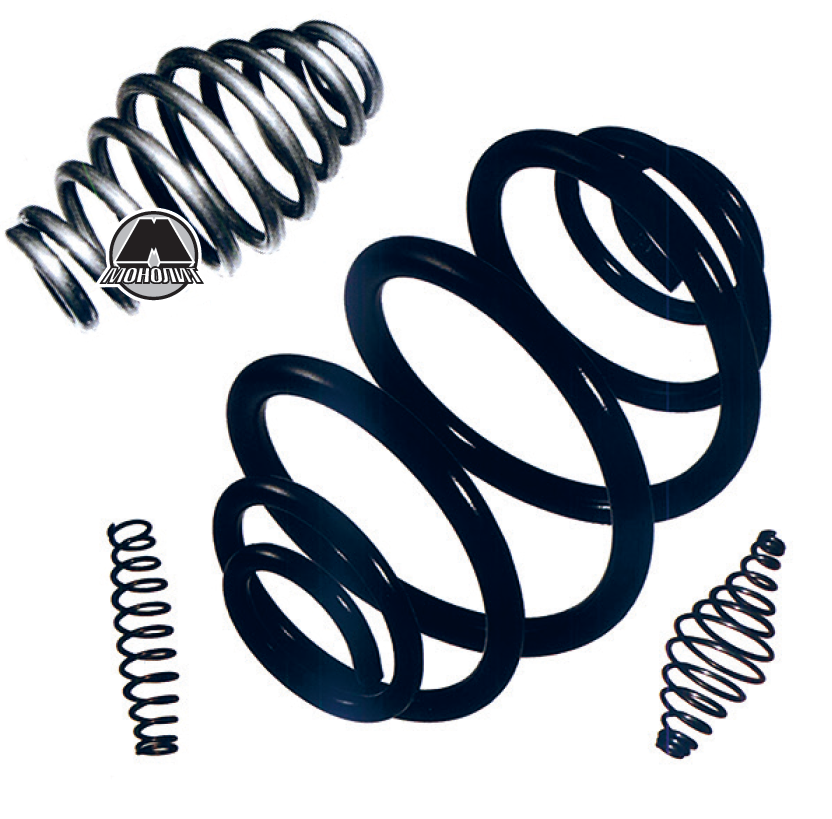

Spring is the simplest and most commonly used springing element, which is used in suspension design. The simplest version uses a tubular coil spring. However, due to the race for optimizing and improving the performance of the suspension, the springs can take on a wide variety of shapes. Thus, the springs can be barrel-shaped, concave, conical and with a variable diameter of the coil section. This is done in order for the spring stiffness to become progressive. That is, with an increase in the compression ratio of the springing element, its resistance to this compression should also increase. The dependence function should be nonlinear and continuously increasing. An example of a diagram of the dependence of the arising stiffness on the amount of compression is shown in Figure 6.12.

In ordinary tubular coil springs, this dependence is linear. Designers started changing the section and pitch of the coil in order to somehow solve this problem.

While changing the shape of the spring (Figure 6.13), they try to bring the stiffness closer to the ideal, guided by the diagram (Figure 6.12).

|

|

|

|

|

Figure 6.12 Diagram of dependence of spring stiffness on compression degree. |

Figure 6.13 Conical springs. |

Figure 6.14 Barrel springs. |

Barrel springs are sometimes called "miniblock" (see figure 6.14 for an example). Such springs, with the same stiffness characteristics as for a conventional coil spring, have smaller dimensions. Contact of the coils is also excluded when the spring is fully compressed.

2 MB