6.1.15 Single-tube gas-filled shock absorbers

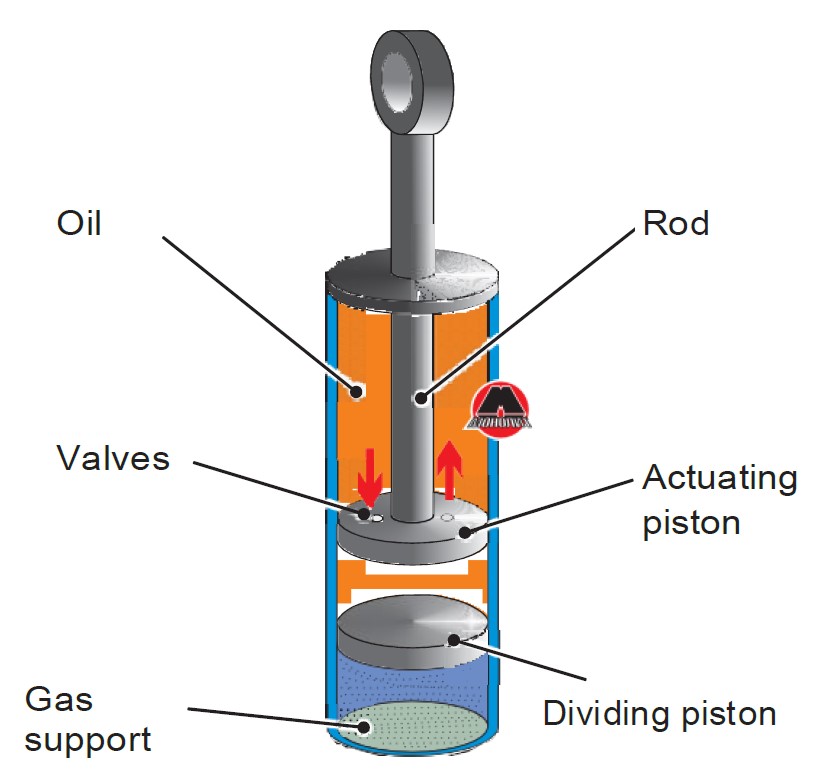

A distinctive feature of these shock absorbers from the aforementioned designs is that they have only one tube. This tube plays the role of both the body and the cylinder. The arrangement of such shock absorber differs only in that it has no compensation valves (Figure 6.10). The piston is equipped with rebound and compression valves. However, a floating piston, which separates the reservoir with the working fluid from the chamber with gas, which is injected under very high pressure (20-30 atm), is a feature of this design.

Do not think that the price is lower if the case is not double. Since only the piston performs all the work, the bulk value of the shock absorber is the cost of calculating and selecting the piston. True, the result of such laborious work is the increased efficiency of all characteristics of the shock absorber.

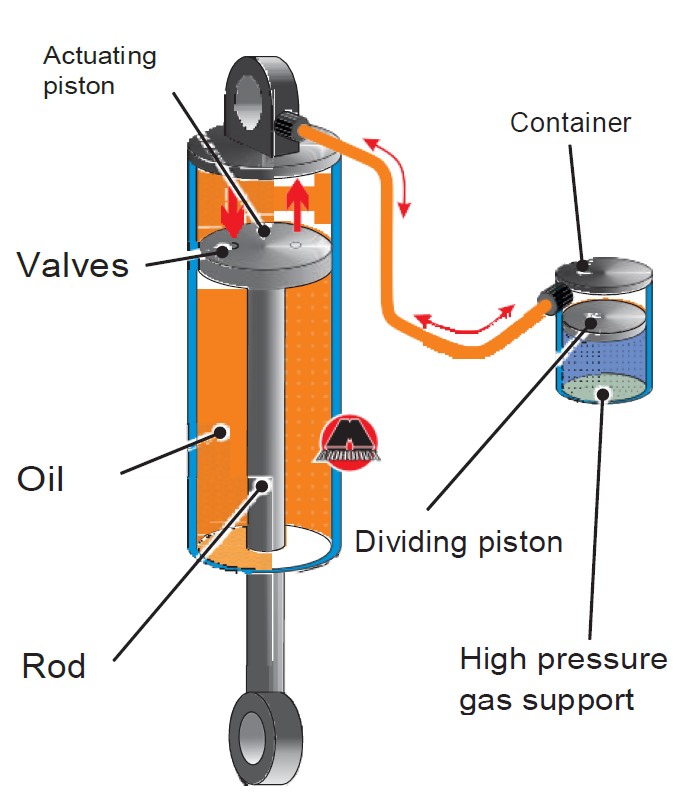

One of the advantages of this layout is that the working fluid inside the shock absorber is cooled much better due to the fact that there is only one wall in the body. Further advantages are the reduction in weight and size and the possibility of installation "upside down" - thus it is possible to reduce the amount of unsprung weights*.

Note

* Unsprung weight is everything between the road surface and the suspension components. We will not delve into the theory of suspension and vibrations. Let's just say that the smaller the unsprung weight, the less its inertia and the faster the wheel will return to its original position after hitting any obstacle.

However, there are also significant disadvantages of gas-filled shock absorbers, namely:

- vulnerability to external damage: any dent will result in a replacement shock absorber;

- sensitivity to temperature: the higher it is, the higher the gas back pressure and the harder the shock absorber works.

|

|

|

Figure 6.10 Single-tube gas-filled shock absorber.

Figure 6.10 Single-tube gas-filled shock absorber. Figure 6.11 Single-tube gas-filled shock absorber, installed with rod upside down.

Figure 6.11 Single-tube gas-filled shock absorber, installed with rod upside down.

2 MB