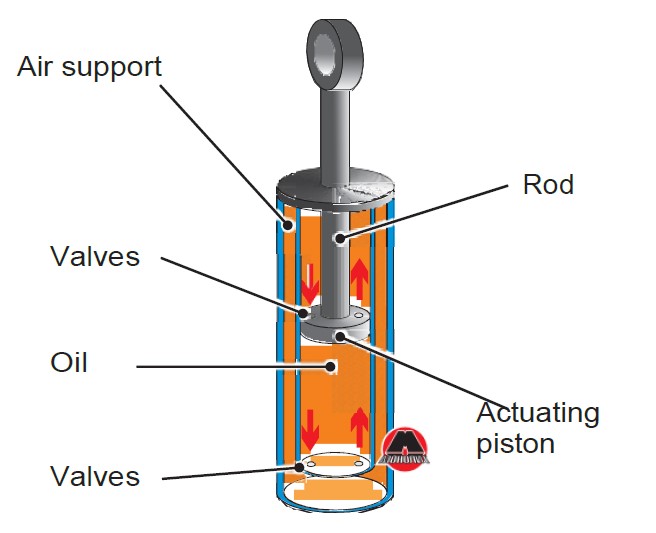

6.1.13 Double-tube hydraulic shock absorbers

The name of this type of shock absorber speaks for itself. The simple type of shock absorber is two pipes, external and internal (shown in Figure 6.9). The outer tube also acts as a housing for the entire shock absorber and as a reservoir for working fluid. The inner tube is called a cylinder. A piston is installed inside it, made as one piece with the rod. The piston has holes in which non-return valves are installed. Some of the valves are directed in one direction, the rest are directed in the opposite direction. Some valves are called compensating valves; others are rebound valves.

Figure 6.9 Double-tube telescopic shock absorber.

Figure 6.9 Double-tube telescopic shock absorber.

Note

Non-return valve is a valve, which only opens in one direction. When applied to a shock absorber, the valves are called rebound and compression valves. Rebound and compression is the stretching and compression of the shock absorber, respectively.

The cavity between the cylinder and the body is called compensational (it is not completely filled with fluid). This cavity, as well as the shock absorber cylinder, are filled with working fluid. On the one side, the cylinder has a hole for the piston rod, and on the other, it is plugged with a plate with holes and one-way valves in them (compensation and compression valves).

When the piston moves in the cylinder, the oil flows from the cavity under the piston to the cavity above the piston, while part of the oil is squeezed out through the valve, which is located at the bottom of the cylinder. Part of the fluid flows through the compression valves to the external expansion tank. There it compresses the air, which was previously under atmospheric pressure in the upper part of the shock absorber body. Since this liquid has a certain viscosity and fluidity, then faster than predetermined, the overflow process will not take place. The same, only in the opposite direction, occurs on the rebound stroke when the piston moves up. In this case, the compensation valves of the cylinder plate and rebound valves inside the piston are activated.

However, this design has one, but a significant drawback: in case of prolonged operation of the shock absorber, the working fluid heats up. It starts mixing with air in the compensation tank and foams. As a result of this, a loss of work efficiency and failure occurs.

2 MB