8.2.2 Hydraulic power steering

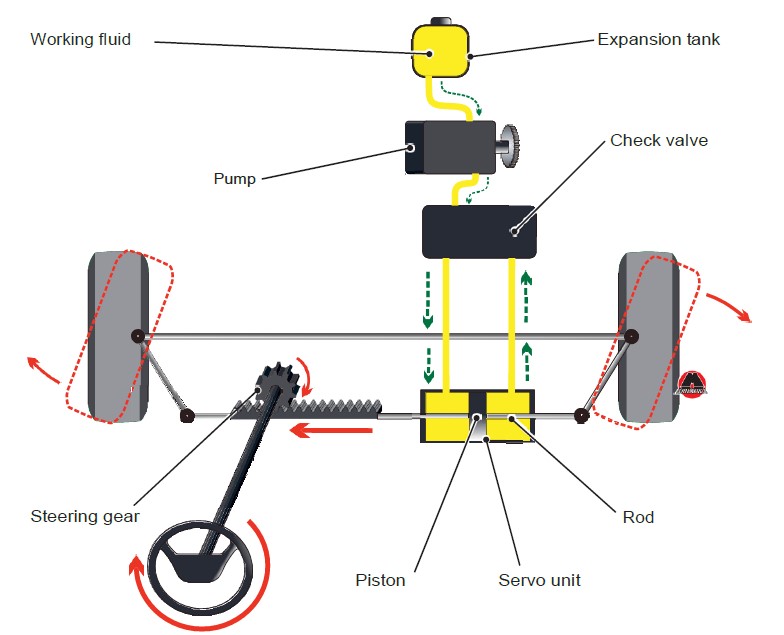

The system with hydraulic power steering consists of the following elements:

- pump (with expansion tank);

- check valve;

- servo unit;

- working fluid itself.

The pump creates an excess pressure of the working fluid in the system. When the steering wheel rotates, the control valve shifts and opens the channel for the working fluid under pressure into the servo unit. The servo unit contains a piston, which is connected through the rod to the steering trapezoid. Under the pressure of the working fluid, the piston moves, creating additional force on the steering wheel, thereby reducing the force required of the driver to rotate the steering wheel.

Depending on the direction in which the steering wheel rotates, the working fluid under pressure is fed into the cavity above or below the piston.

When the steering wheel is located in the center, the pump pumps the working fluid without any load, virtually idle. As soon as the steering wheel starts turning, the fluid pressure inside the system increases and reaches a maximum at the extreme (right or left) position of the steering wheel.

Figure 8.8 Functional diagram of the hydraulic power steering system.

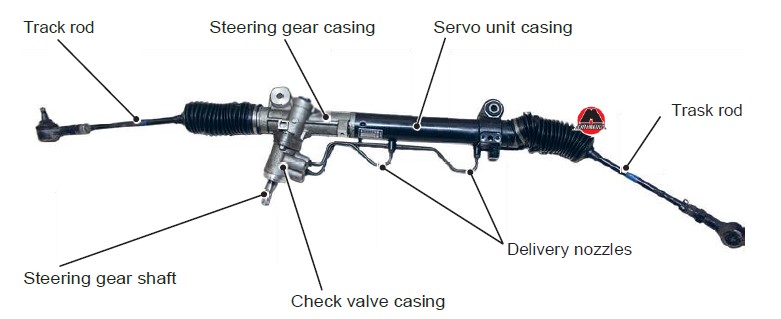

Figure 8.9 Steering gear with hydraulic power steering..

Note

In a vehicle with a hydraulic power steering, it is forbidden to hold the steering wheel in one of the extreme positions for a long time, because this may damage the booster pump.

The pump can be driven by a belt from the engine or from a separate electric motor.

2 MB