5.3.12 Вариатор - принцип работы

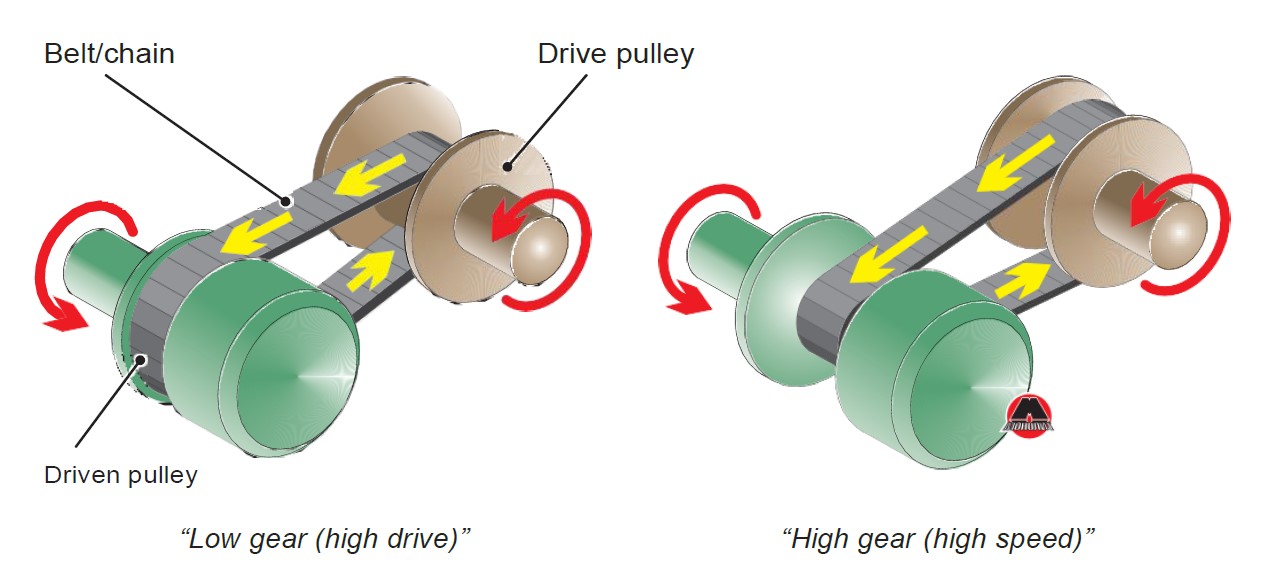

During the start of the movement, when it is necessary to supply the maximum torque to the drive wheels, the halves of the drive pulley are separated maximally, and the driven pulley is installed with a minimum clearance (left side of Figure 5.26). In this case, the belt seems to fall between the two halves of the drive pulley. Thus, the actual working diameter of the belt on the drive pulley is minimal. And on the driven pulley it is maximum, which achieves the highest gear ratio and, accordingly, the highest torque. As the speed increases, the parts of the driving pulley draw together a little, and the parts of the driven pulley move apart. The gear ratio changes smoothly (right side of Figure 5.26).

Примечание

In variators, the range of gear ratios is limited only by the size of the pulleys.

Figure 5.26 Variator operating principle.

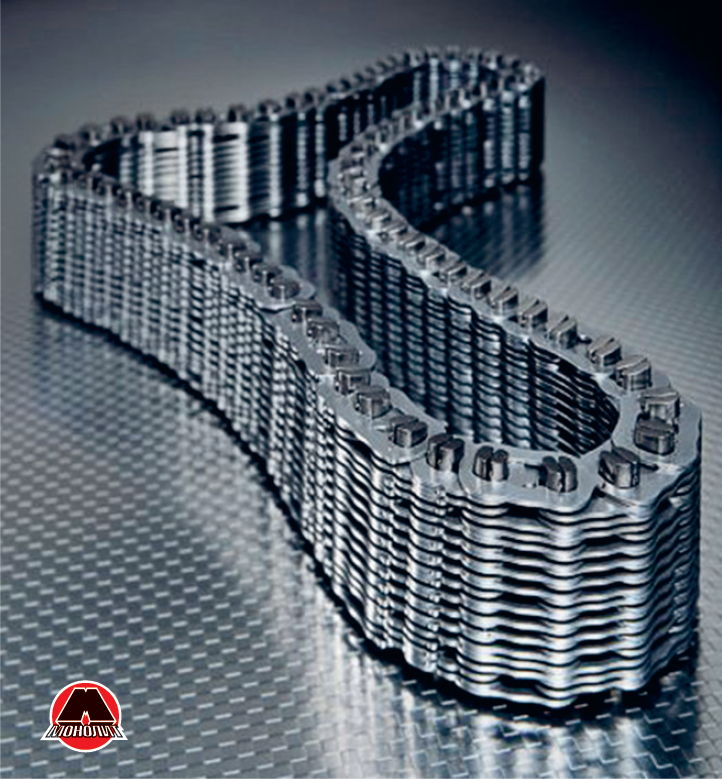

One of the main disadvantages of this type of variator was the small resource of the V-belt, which is located between the pulleys. With the development of technology, the V-belt was replaced by a chain (an example of a chain in Figure 5.27) or, in some cases, by a composite metal belt.

Figure 5.27 Chain, which is used in modern variators.

2 MB