5.3.14 Toroidal variator

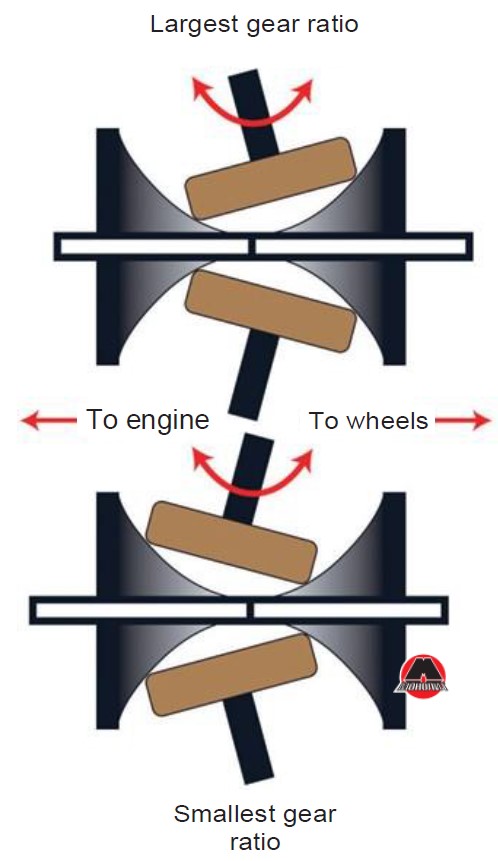

A toroidal variator is rarely used. But nevertheless it is an excellent attempt by automakers to get rid of the main drawback of V-belt variators - the belt itself. A toroidal variator consists of two oppositely installed cones with concave walls. Two rotors are installed between these cones. They are pressed with a very high force and have the ability to move along the surfaces of the cones, as shown in Figure 5.28.

Figure 5.28 Operating principle of the toroid variator.

One of the cones is the drive, the second is the driven one. Rotation from the driving cone is transmitted to the driven cone via pulleys. At the beginning of the movement, when the gear ratio should be maximum, the pulleys are turned and installed so that they are as close as possible to the top of the driving cone, and to the base of the driven cone. It turns out that the actual diameter of the driving pulley is less than the actual diameter of the driven pulley by the value of the gear ratio. One cone rotates. This rotation is transmitted through the pulley to the second cone. In order to change the gear ratio, it is necessary to move the pulleys in the opposite direction - in the direction of increasing the actual diameter of the drive pulley.

Note

The toroidal variator is named after the figure torus, and in no way is it connected with the ancient Scandinavian ace, the god of thunder and lightning - Thor.

2 MB