5.2.10 Gearbox device

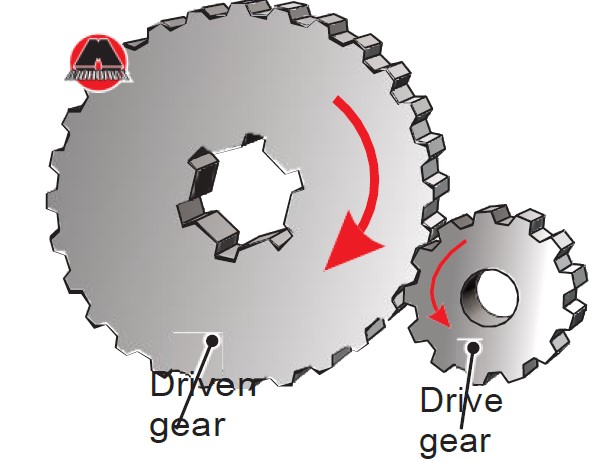

The change in the ratio between the number of revolutions of the crankshaft of the engine and the driving wheels and the change as a result of this tractive effort on the wheels is carried out using toothed gear wheels (gears), of which the gearbox consists. An example of a gear pair, which consists of a drive and driven gear, is shown in Figure 5.7.

Figure 5.7 Gear set (gear pair)

Figure 5.7 Gear set (gear pair)

When the small drive gear rotates (Figure 5.7), the large driven gear, which is meshed with it, will rotate more slowly as many times as the number of its teeth. In this case, the torque on the axis of the driven gear will increase by the same amount.

The ratio of the number of teeth (or diameters) of the driven gear to the number of teeth of the driving gear is called the ratio of number of teeth (or gear ratio). The greater the gear ratio of the gear pair, the more significantly the number of revolutions of the gear shafts and the torque on them change. The action of gearboxes is based on changing gear ratios by engaging gears with different numbers of teeth.

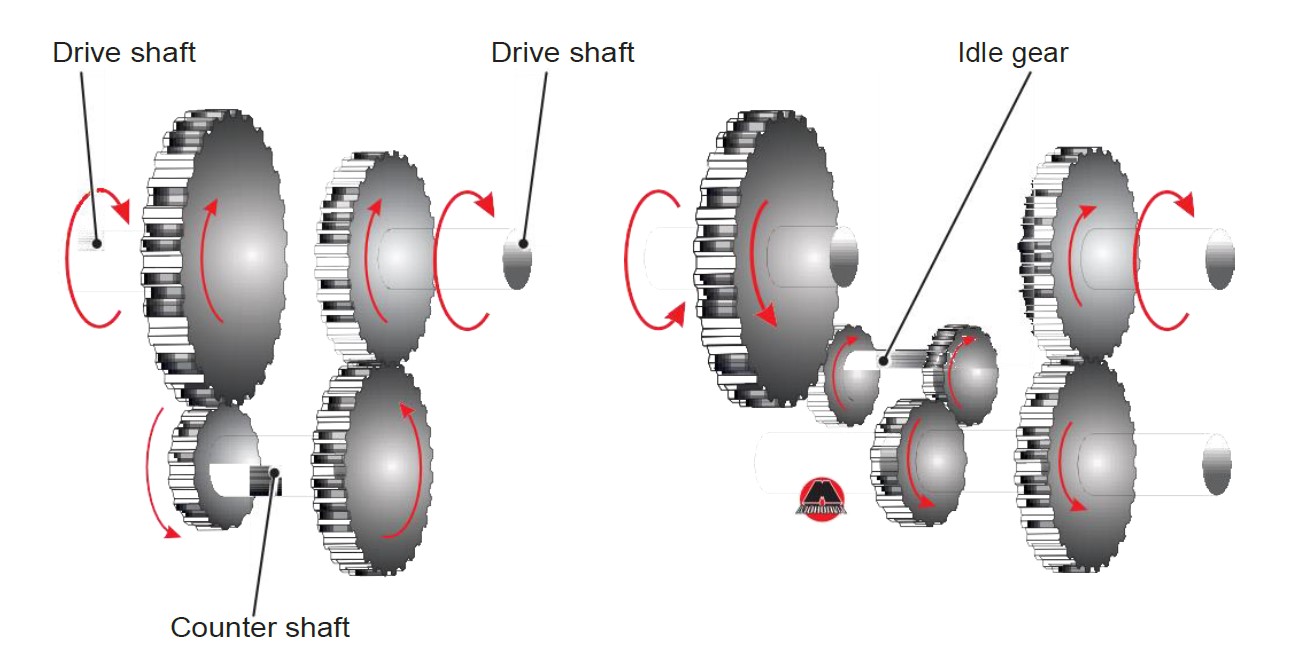

Enabling the car to go in reverse is another of the important functions of the gearbox. This function is based on the inclusion of an intermediate gear between the driving and driven gears - the so-called "idle gear".

Thus, when transferring force in the box without turning on the parasitic (intermediate) gear, the drive shaft (Figure 5.8) and the driven shaft rotate in the same direction. When the idle gear is turned on, the driven shaft starts rotating in the opposite direction and the car moves back.

Interesting

Gear ratios are never integers. Rather, when calculating them, one tries to choose so that they are not integers. For clarity, it is worth providing an example: there are two gears, we take a marker and put two marks - one opposite the other - on both gears. In case if the gear ratio between these gears is, for example, three, then after exactly three revolutions the marks applied to the gears will meet again. This will reset the teeth to their original position every three turns. This will lead to the fact that one pair of teeth will be three times more loaded than the others and, as a result, will wear out faster or break altogether. That is why, when selecting gear ratios, manufacturers try to make them not integer.

Figure 5.8 Simplified layout of single-stage gearbox.

Figure 5.8 Simplified layout of single-stage gearbox.

2 MB