7.2.3 How brakes work

Principle of operation of this system is as follows: the brake pedal through the rod is connected to the piston, which moves inside the master brake cylinder (shown in Figure 7.2), filled with brake fluid, as, indeed, all pipes and hoses of the brake system. When you press the brake pedal, the piston moves inside the cylinder, presses on the fluid, which transmits the force to the wheel brake cylinders of the brake mechanisms. Everything is simple. If it is not clear, you should not immediately be embarrassed, because the operation of each element of the brake system will be described later in the chapter.

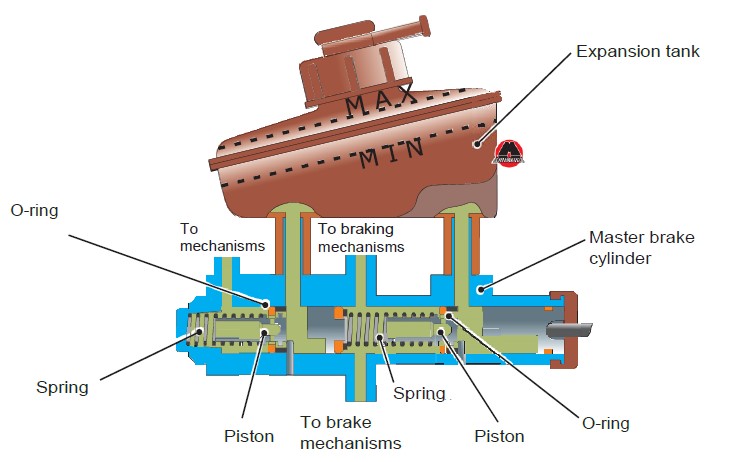

Figure 7.2 Example of master brake cylinder with expansion tank.

In addition to the fact that with the help of the main brake cylinder, the force is transmitted from the pedal to the brakes, it also ensures the separation of the circuits (see below).

An expansion tank, which is necessary to compensate for the expansion of the brake fluid when it heats up and to prevent air from entering the hydraulic brake system, is installed above the master brake cylinder (in order to achieve this, you shall always monitor the level of the brake fluid in the reservoir and do not allow it to fall below the "MIN" mark).

The expansion tank is divided into two tanks (or has one tank, but with a dividing wall), that communicate with the master brake cylinder of the system through two holes. The pistons have O-rings that are pressed by springs.

Note

In addition to the groove, the pistons have annular cavities and flat angular grooves that connect to the tank at any position of the pistons. This prevents air from entering inside the hydraulic line.

Note

One of the most dangerous, from the point of view of hit of air in the master brake cylinder, is the moment of the mode of deceleration, which is often carried out sharply by a pedal throw. In this case, the fluid due to its certain viscosity returns to the master cylinder relatively slowly, and the pistons under the action of springs tend to break away from the fluid. This results in a discharge in the line. At the same time, it is almost impossible to exclude air hit in the highway only by consolidations therefore on the back party of pistons or in them cavities filled with liquid have.

Technologies are evolving and, in order not to burden the driver with constant checks of the brake fluid level, a float is installed in the expansion tank and a brake fluid level sensor is connected to it. As soon as this very level falls below the set, the corresponding alarm will light up on the dashboard in the car passenger compartment, and maybe even the sound alarm will be actuated.

Note

It is almost impossible to exclude air entering the hydraulic drive of the brake system. Thus, during the replacement of any elements of brake system it is necessary to drain a part of brake liquid. And it is impossible to fill the system with fresh brake fluid without air ingress. Also, when the brakes overheat, the fluid may start boiling, forming air bubbles.

There so-called breathers in order to remove air from the hydraulic brake are installed in the uppermost points of each element of the brake system. The breather is a hollow bolt acting as a valve, but with a "manual drive". While unscrewing the breather, the “valve” opens, and while screwing it, the valve closes.

Note

Information on how to perform operations to remove air ("pumping", simply put) from the hydraulic brake system, can be found in any book on car repair and maintenance.

Working cylinder is the final element of the hydraulic drive. In case if the brakes are drum, then the working cylinder is a separate part. In case if the brakes are disc, then it is integrated into the caliper of the brakes (see Figures 7.3 and 7.4).

2 MB