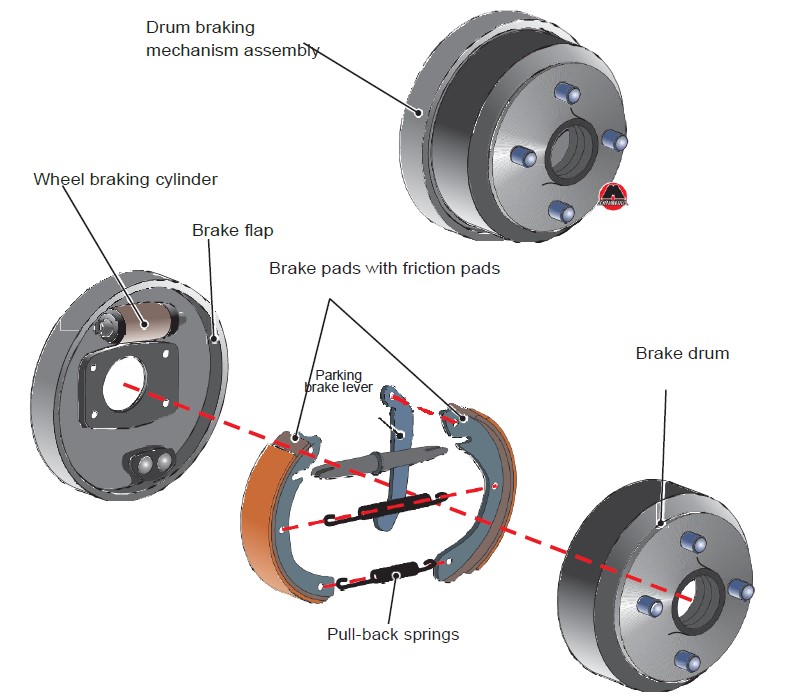

7.2.6 Drum brakes

At one time it was a very common type of brakes. Its arrangement is very simple (Figure 7.3): brake flap, which is non-rotating and rigidly fixed on the steering knuckle* (in case if the front wheels are steerable) or on an axle journal (in case if it is the rear axle), the brake flap has a wheel brake cylinder and brake pads that rest on one end and rest on the other in pistons of the wheel brake cylinder. Friction pads are glued or riveted on the brake pads. All these parts are covered with a brake drum, which rotates along with the wheel.

In case if it is suddenly necessary to reduce speed or to stop the car, the driver, pressing a brake pedal, through the hydraulic actuator acts on pistons of the wheel brake cylinder which, moving, spread brake pads, pressing them to a surface of a brake drum.

There are several layouts of brake pads.

* If anyone has forgotten, you can see what the steering knuckle looks like in Chapter 6, Figure 6.4.

Figure 7.3 Example of drum braking mechanism.

Interesting

In the drum brake mechanism, which is shown in Figure 7.3 (one of the most common layout of pads), the two pads are installed in series. One brake pad is front, the other is rear (in the course of movement). Both these brake pads are installed on axes from below. And from above these pads rest against pistons of the working cylinder. When braking, the forces will act so that the front brake pad will be wedged, and the rear pad will try to move the forces from the drum. This can cause uneven wear of the friction pads. Also, this effect leads to the fact that the working surfaces of the friction pads are not fully used.

Pull-back springs are installed in order for the brake pads to return to their original position after braking.

The clearance between the pads and the drum is often adjusted automatically. This is implemented simply: the pistons of the wheel cylinders, while moving outwards under the action of fluid pressure, will choose the axial gap between them and the elastic rings, and then pull the rings behind them. The movement of the pistons will continue until the pads rest against the drum. When the pedal is released, the pull-back springs will only be able to move the pistons back at a distance, which corresponds to the axial clearance between the piston and the ring, as they are unable to move the ring. The size of the gap, as it was mentioned above, corresponds to the required gap between the pad and the drum. Thus, as the pads wear, the ring will move along the cylinder, maintaining a constant amount of clearance in the mechanism.

Drum braking mechanisms have a number of advantages over disc brakes, but there are many disadvantages.

Advantages:

- large working surface of brake pads and a possibility of its increase both at the expense of diameter of a brake drum, and at the expense of its width (useful property for trucks);

- relative protection of the brake mechanism from dust and dirt;

- resistance of elements of the braking mechanism to temperature difference.

Disadvantages:

- low power if compared to disc brakes;

- big inertia of elements of the braking mechanism;

- sensitivity to overheating.

2 MB