6.2.2 Wheel types

The following types of propellers are distinguished:

- driving;

- driven;

- combined (driving and driven);

- idle (non-driving and uncontrollable, for example, trailer wheels or supported in multi-axle trucks).

Driving propellers got their name precisely because they convert the engine thrust into the forward motion of the car, transferring all the moments and forces to the road. The driven propellers are solely responsible for controlling the direction of movement of the vehicle. And in case if the propeller receives thrust from the engine, and even is responsible for the direction of movement, then it is combined. Idle propellers are used for evenly distributing the weight of the vehicle on the road surface.

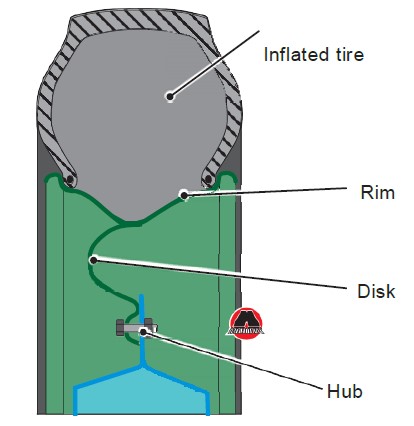

Wheel propeller (Figure 6.20) consists of inflated tire, a hub and a wheel (which consists of a disk and a rim).

Figure 6.20 Wheel propeller. Cross-section.

Inflated tire is the most important element in the wheel propeller design. If we imagine a wheel propeller without a pneumatic tire - rigid, for example, a wooden one, then it is easy to assume that when it rolls on a solid road, the trajectory of the axle movement will copy the road profile. In this case, the impacts of the wheel propeller on bumps will be fully transmitted to the suspension. And everything looks very different when the wheel propeller has an inflated tire. At the point of contact, an elastic tire (usually made on the basis of rubber and various additives - from soot to silicon oxide) deforms. At the same time, small bumps that deform the tire do not affect the position of the wheel axis of rotation.

In case if the wheel propeller runs into more significant obstacles, then strong shocks cause increased deformation of the tire and a smooth movement of the axis of rotation of the wheel. The ability of a pneumatic tire to smoothly change the negative effect of road surface defects on the wheel axis of rotation is called smoothing.

The smoothing effect is provided by the elastic properties of the compressed air in the tire.

Note

When a part of the tire rolls out of contact with the road surface, a fraction of the energy, which is expended in deformation of the tire, is spent on internal friction in the rubber, turning into heat. Heating has a negative effect on the properties of tires, as a result - accelerated wear. Energy loss depends on tire design, internal air pressure, load, travel speed and transmitted torque. In case of an increase in the deformation of the tire, the losses for internal friction also increase. The consequence of this is an increase in the power, which is expended on the movement of the car. The air pressure in the tire must be increased in order to reduce deformation and irreversible losses. However, in order to meet the requirements for ensuring a high smoothing ability of the tire, on the one hand, and to reduce irreversible losses on internal friction, on the other, the air pressure in tires of each type is set taking into account their design features and operating conditions.

The air pressure in the tire of the wheel is the most important performance indicator. It is set by each manufacturer according to the design and intended purpose of the tire.

2 MB