4.5.3 About expansion gap

There must be a gap (the so-called expansion gap) between the valve rod and the push rod or the end of the rocker arm of the gas distribution mechanism, which is necessary for compensating for the elongation of the valve rod when it heats up without disturbing the tightness of the valve seating in the valve seat. In other words, if there was no gap between the camshaft cam and the valve, then the valve in the process from heating to high temperature would increase in length and cease to fit tightly against the seat in the cylinder head.

The value of the expansion gap for engines of different brands is set for intake valves in a cold state in the range of 0.15-0.30 mm, and for exhaust valves that are exposed to greater heating - in the range of 0.20-0.40 mm. However, for some manufacturers, this gap may differ from the above values.

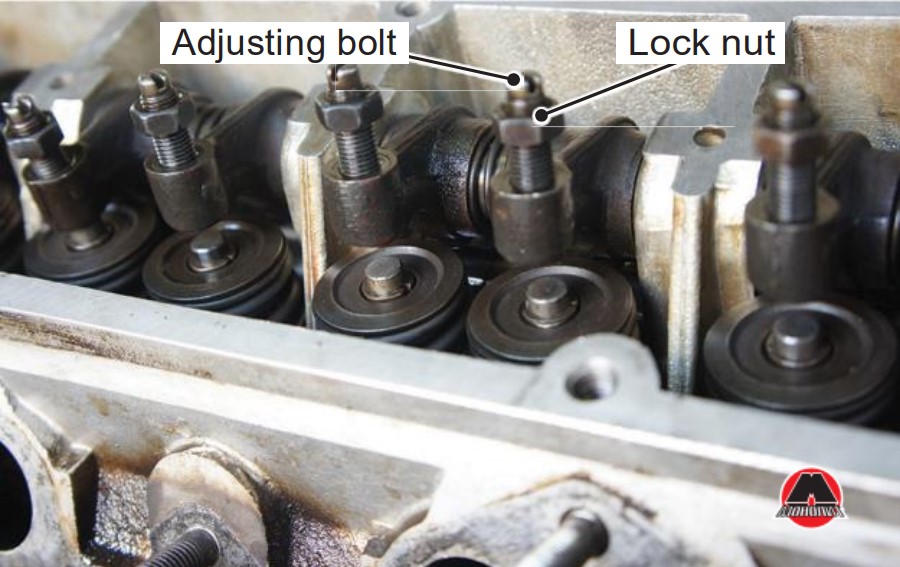

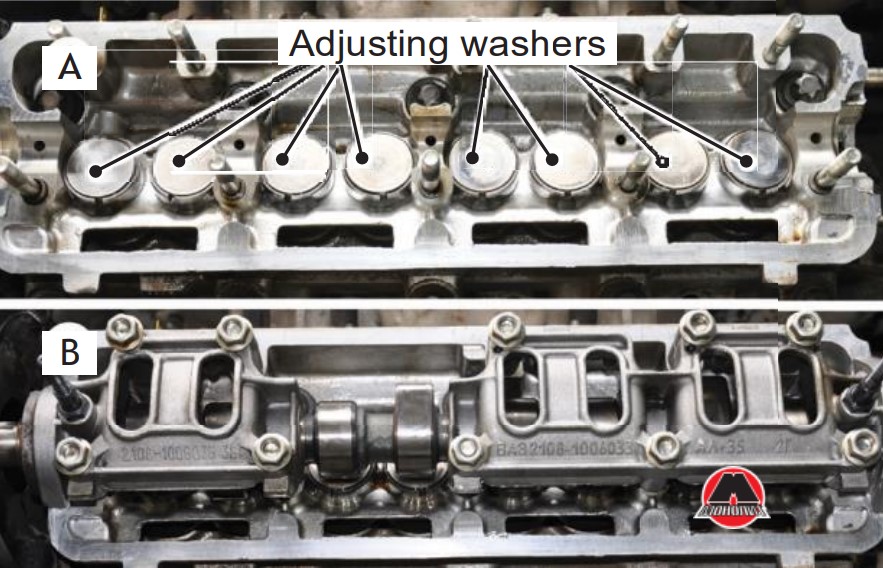

Adjusting devices are installed on this mechanism in order to adjust the size of this gap. Although the word "device" would be too loud for an adjusting bolt and lock nut (figure 4.9) or washers of different thicknesses (Figure 4.10).

Figure 4.9 Adjustment of the expansion gap using the bolt.

Figure 4.10 Adjustment of the expansion gap using nuts (А – cylinder head without camshaft; B – cylinder head with camshaft).

Nowadays, a design with hydraulic lifters is very common. Under the influence oil pressure it pushes the rocker arm or push rod to the camshaft cam, thereby removing the negative effect of the expansion gap, namely, the impact of the cam on the push rod during operation. But it is worth mentioning that the installation of hydraulic lifters increases the cost of the design of the cylinder head and increases its requirements for the quality of the engine oil, which is used and for the frequency of its replacement, since the oil channels of the lifter can be clogged with wear products.

Note

Hydraulic lifters are described in more details below.

2 MB